公司新闻

上海冷轧硅钢现货 B35AV2100欢迎订购

更新时间: 2026-02-13 06:59:53 ip归属地:攀枝花,天气:晴转多云,温度:7-18 浏览:2次

以下是:四川省攀枝花市上海冷轧硅钢现货 B35AV2100欢迎订购的产品参数

| 产品参数 | |

|---|---|

| 产品价格 | 2/吨 |

| 发货期限 | 3天内 |

| 供货总量 | 50000 |

| 运费说明 | 电议 |

| 小起订 | 1 |

| 质量等级 | 精品 |

| 是否厂家 | 是 |

| 产品材质 | 冷轧 |

| 产品品牌 | 宝武日本进口 |

| 产品规格 | 0.08-0.65 |

| 发货城市 | 上海武汉 |

| 产品产地 | 上海武汉 |

| 加工定制 | 粗加工 |

| 产品型号 | 多种 |

| 可售卖地 | 全国 |

| 质保时间 | 一年 |

| 适用领域 | 电器马达电机变压器磁感器互感器稳压器继电器电磁开关新能源电机电动汽车变压器军工电机发电机组航天造船汽车等 |

| 是否进口 | 否 |

| 品名 | 电工钢 冷轧无取向电工钢 冷轧取向电工钢卷冷轧取向硅钢 取向电工钢冷轧无取向硅钢冷轧无取向硅钢 |

| 规格 | 0.08 0.1 0.05 0.18 0.2 0.23 0.27 0.3 0.35 0.5 0.65 1.0mm |

| 包装 | 原厂精包装 |

| 用途 | 电器马达电机变压器磁感器互感器稳压器继电器电磁开关新能源电机电动汽车变压器军工电机发电机组航天造船汽车等 |

| 范围 | 上海冷轧硅钢 B35AV2100欢迎供应范围覆盖四川省、成都市、绵阳市、攀枝花市、泸州市、乐山市、宜宾市、广安市、巴中市、甘孜市、凉山市、阿坝市、资阳市、雅安市、遂宁市、内江市、南充市、自贡市、德阳市、广元市、眉山市 仁和区、米易县、盐边县等区域。 |

【鹿程】业务覆盖多领域场景,主营米易电工钢、盐边电工钢、绵阳汽车大梁钢、南充电工钢、眉山冲压用钢、巴中汽车钢等产品服务。在四川省攀枝花市本地采买上海冷轧硅钢现货 B35AV2100欢迎订购到鹿程国际贸易(攀枝花市分公司),无论您是个人用户还是企业采购,我们都将竭诚为您服务。品质保证,价格优惠,厂家直销,欢迎有需要的客户来电。联系人:鹿丙伟-【0527-88266888】。 四川省,攀枝花市 攀枝花市,四川省辖地级市,别称渡口、钢城,地处中国西南川滇结合部,位于四川省南端,东、北面与四川省凉山彝族自治州的会理、德昌、盐源3县接壤,西、南面与云南省的宁蒗、华坪、永仁3县交界,地处攀西裂谷中南段,属浸蚀、剥蚀中山丘陵、山原峡谷地貌,夏季长,四季不分明,而旱、雨季分明,全市总面积7440平方千米。截至2022年10月,全市辖3个区、2个县。截至2022年末,攀枝花市常住人口121.6万人。

文字或许能描绘上海冷轧硅钢现货 B35AV2100欢迎订购产品的轮廓,但视频却能赋予它生命。每一帧都是一次全新的体验,每一次点击都是一次心灵的触动。快来观看,让产品活起来!

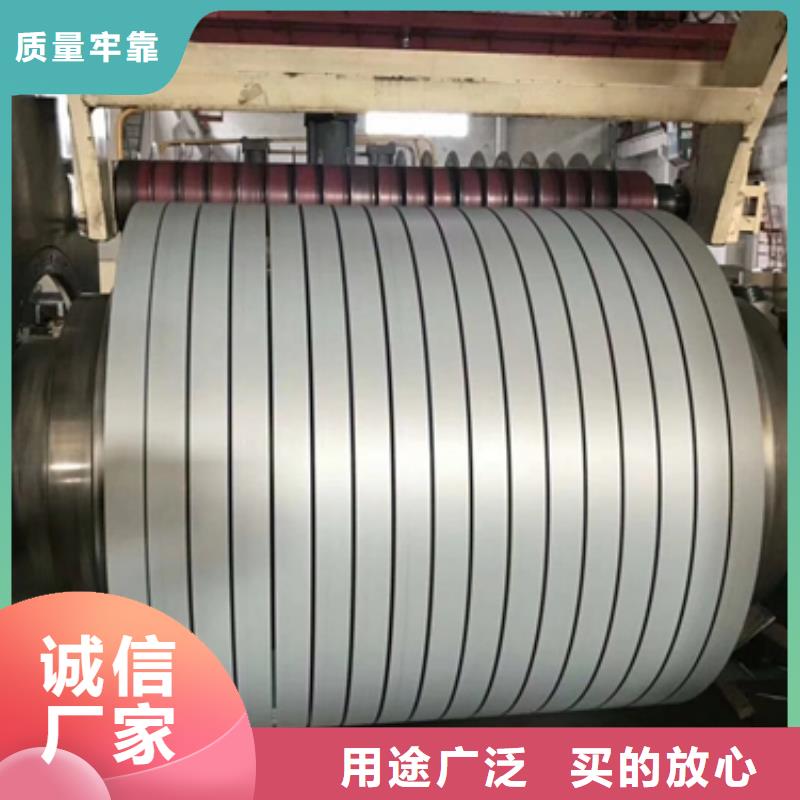

以下是:四川攀枝花上海冷轧硅钢现货 B35AV2100欢迎订购的图文介绍

鹿程国际贸易(攀枝花市分公司)坚持“以诚信树品牌,以创新求发展”,通过不断的创新与超越,在 硅钢产品创新、管理创新、公司发展上实现与时代同步,成为行业的典范,铸造于 硅钢“的可持续发展的美好愿景。公司组建了由不同地区、不同城市近50位人才构成的好的设计与施工团队; 硅钢成功案例遍及北京、天津、河北、山西、江苏、浙江、云南、湖南等多个城市。

电工钢硅钢片Intro of iron core of automobile driving motor。At present, the motor technology of high-speed punching of stator and rotor iron core at home and abroad has developed rapidly. With the development of stamping equipment, new equipment with high quality, high efficiency and high precision has been provided for the production of motor punching pieces of high-speed punching of stator and rotor iron core at home and abroad, which has brought the motor punching process technology. Therefore, the design technology of new technology and equipment suitable for it has become a new research topic. The simultaneous separation of stator punching groove and stator punching groove of motor high-speed punching stator rotor iron core the simultaneous cutting of air gap between rotor punching and rotor punching groove is a new technological scheme applied to high-speed punching machine. This scheme has been widely used in foreign countries and has just begun research and application in domestic motor industry. Therefore, some discussions are made to realize the design technology of this technology according to the required technological equipment.The influence of motor high-speed punching of stator and rotor iron core: the influence of motor punching process technology of motor high-speed punching of stator and rotor iron core in new product development the traditional process of motor punching in our country is two categories: double punching and single punching, which are analyzed as follows:1) the process scheme of double punching groove: this scheme has good groove shape and uniformity, few processes and few tooling, but the tooling is complex and requires high precision, good equipment conditions, long tooling manufacturing cycle and Cheng Bengao, which is only suitable for mass production and is not conducive to new product development and small batch trial production.2) single-type punching process scheme: this scheme has poor groove shape, many processes, many tooling, many equipments, simple tooling, unstable quality, long production cycle and Cheng Bengao, and is only suitable for medium and small batch production.Requirements for high-speed punching of stator and rotor iron core of motor: 1. Positioning accuracy requirements. In this technological scheme, the two composite processes of punching groove separation and punching groove cutting air gap require the same positioning Benchmark, ensuring that the concentricity of the groove shape of the stator and rotor, the outer circular dove tail groove and shaft hole is not more than 0.02mm, the positioning of the center hole meets the technical requirements of concentricity, and the joint positioning of the small side hole and the center hole meets the requirements of circumferential orientation. 2. Precision requirements of composite process. Punching and groove separation compound process: This process has Groove-shaped convex mold and incision convex mold to complete the progressive blanking process. This process first punches and then cuts to separate the fixed and rotor punching pieces. The Two convex molds act synchronously on the same center track, and the central included angle between the two convex molds is one and a half times the central included angle of the groove. This process equipment is applied to high-speed punching machines, the groove-shaped indexing accuracy is guaranteed by the CAM stepping mechanism on the equipment;Electric vehicle is an economical and clean green vehicle based on electric drive,Environment and other aspects have * competitiveness, and can conveniently use modern control technology to realize its electromechanical integration, with broad development prospects.The motor drive system of the iron core of the automobile drive motor is the power source of the electric vehicle, and is the main body and internal basis for determining various performance indexes of the automobile operation. At present, electric vehicle motors mainly include DC motors, induction motors, permanent magnet brushless motors and switched reluctance motors.Automobile drive motor iron core permanent magnet brushless motor can be divided into two categories: one is permanent magnet synchronous motor with sine wave current,The other is the BLDC motor with rectangular pulse wave current.Two kinds of motors, the rotor is magnet, the motor rotor does not need brush and excitation winding, through stator winding commutation to generate rotating torque. Because the rotor has no excitation winding, no copper consumption, small magnetic flux and very small iron consumption at low load, therefore, the permanent magnet brushless motor has a high "Power/mass" ratio and can run at high speed. At the same time, it is easy to cool down because there is no abrasion of the rotor and the stator winding is the main heat source.The characteristics of the iron core of the automobile driving motor; The permanent magnet brushless motor of the iron core of the automobile driving motor has high reliability and high output power. Compared with other motors with the same rotating speed, it has the characteristics of small volume, light weight, easy maintenance, high efficiency, high power factor, etc. The rotor has small electromagnetic time constant and good dynamic characteristics of the motor. Through adjustment and conduction angle, constant power operation can be realized, and the efficiency of the motor can also be optimized by optimizing control angle, thus obtaining wider constant power operation area and higher efficiency.Overview of motor high speed punching stator and rotor iron core

电工钢硅钢片绝缘涂层取向电工钢产品表面均涂以一层无机绝缘涂层,该涂层具有优异的涂层特性:层间电阻高—层间电阻高,确保良好的层间绝缘性。冲片性能优—涂层与底层紧密结合,具有良好的附着性,可防止加工时涂层脱落。 叠片系数高—表面涂层均匀且薄,具有优异的叠片性能。耐热性能好—涂层能承受800℃退火,且不被损坏。耐蚀性能好—涂层与冷却油、四川攀枝花同城绝缘油、四川攀枝花同城机械油及氟里昂、四川攀枝花同城防冻油等不相容,免受侵蚀。电工钢主要分为晶粒取向电工钢和晶粒无取向电工钢两大

您是想要在四川省攀枝花市采购高质量的上海冷轧硅钢现货 B35AV2100欢迎订购产品吗?鹿程国际贸易(攀枝花市分公司)是您的不二之选!我们致力于提供品质保证、价格优惠的上海冷轧硅钢现货 B35AV2100欢迎订购产品,品种齐全,不断创新,致力于满足广大客户的多种需求,联系人:鹿丙伟-【0527-88266888】,地址:《宝山区蕰川公路777号宝钢厂区607-609室》。

其他新闻

- 巴彦淖尔市钢结构厂房出售 2026-02-13

- 铝合金桥梁栏杆性能好 2026-02-13

- 不锈钢吸烟亭畅销全国 2026-02-13

- 宝钢超高强钢板 BMS1000宝钢热轧容器钢板 2026-02-13

- 防撞铁艺仿木栏杆加工 2026-02-13

- 收购粉末涂料本地高价收购 2026-02-13

- 声测管沉降板连接加工厂家 2026-02-13

- 房地产精神堡垒雕塑欢迎订购 2026-02-13

- 薄型通风气楼供应商 2026-02-13

- 新款候车亭10年经验 2026-02-13

- led屏回收_回收灯带专业回收 2026-02-13

- 钢闸门-滑动钢制闸门库存丰富 2026-02-13

- 截流井液压限流闸门市政专用 2026-02-13

- CT室铅门上门安装宠物铅房 2026-02-13

- 磐金无缝管定尺加工 2026-02-13

- 大庆三维植被网,车库虹吸排水系统 精品选购 2026-02-13

- 云浮无缝钢管高压炉管厂家品质保证实力见证 2026-02-13

- 张掖正大镀锌钢管全国发货 2026-02-13